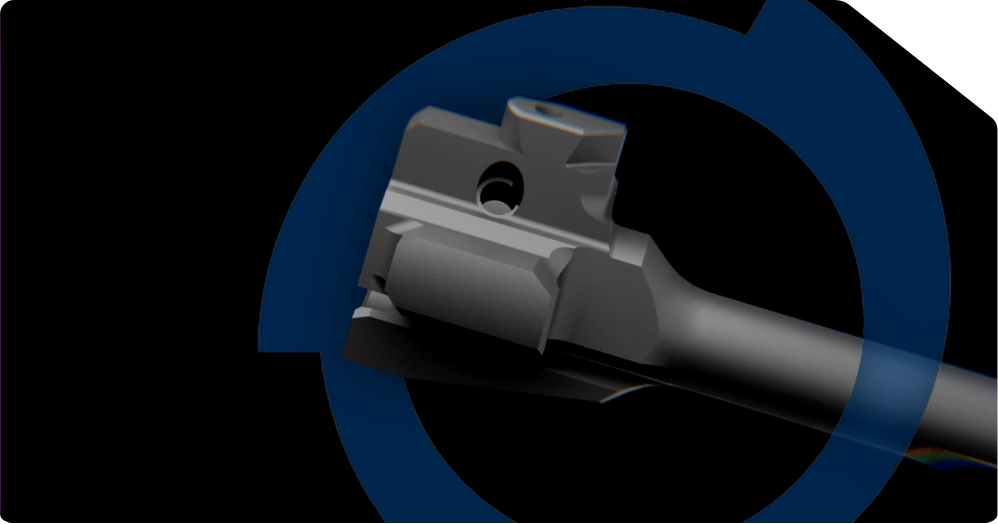

Swiss Machining Services

It’s how we’ve run for years, and we’ve seen both ourselves and our customers succeed through our dedication to only top-tier Swiss Machining technology and techniques. Swiss Machining has many advantages, including the capability to machine longer, slender, and more complex parts with incredible accuracy, efficiency, and throughput.

From small runs of a few hundred pieces up to hundreds of thousands, Swiss Machining allows us to manufacture complex components on one machine. High-volume production runs with our advanced machining can cover numerous steps in the process including milling, threading, drilling, boring, turning, and other custom requirements. To benefit customers while ensuring accuracy, one machine can perform synchronous operations in a shorter period of time while offering us more control in the production of your complex parts.

In-House Services

In order to keep projects moving and ensure the best production quality, we provide a variety of capabilities under our own roof. This allows for parts to be monitored and seen through the crucial stages of production, making for a smooth and controlled process. Learn more about our in-house services.

Tumble / Deburr & Polishing

We use Centrifugal and vibratory deburring and polishing. Our services range from aggressive deburring and edge breaking to intricate polishing. These processes are used for everything from food contact components to metal prep for visual aesthetics in final plating.

Sandblasting

As an important step in many of our projects, this process is used for plating preparation, cleaning parts after heat treating to remove scale and residue, general deburring, and provides uniform surface finishes to all materials.

Parkerizing / Manganese Phosphate

This process is commonly used in the firearm industry to provide both corrosion resistance and lubrication between moving parts, this also serves as a foundation for subsequent coatings for painting. Our skilled team has years of experience in this unique application.

Minor Assembly

We excel at creative solutions for small component assembly. We make the parts, complete the secondary processes to those parts, and then assemble them to help companies simplify inventory management, reduce scrap, lost components, and skilled labor requirements.

Design for Manufacturing

We work closely with engineering teams to look for overall cost savings though simplifying designs. Sometimes simple things like changing a tolerance, an angle, or a radius can drastically reduce machining time and results in cost savings to the customer. We continually work to retain fit, form, and function to make the most cost-effective components.

Value-Added Services

In addition to our core services, we also provide several value-added services offered by our Certified Vendor partners to complete your project to your exact specifications. Learn more about our extensive value-added services.

Heat Treat

We work with local and trusted heat treating companies to provide components that meet all your metallurgical requirements. We use heat treating on several materials, including carbon steels, stainless and most alloys.

Grinding

When surface finish requirements and tolerances require it, we work with local, pre-selected grinding companies to provide cost-effective solutions to meet them for our customers.

Plating / Anodizing / Black Oxide

No matter what your project calls for, we work with a large variety of selected vendors to supply your finishing needs. We provide several options that can take care of the finished product using Black Oxide, Zinc plating, Gold plating, Phosphate and Oil, Electroplating, and Anodizing.

Passivation / Washing

From Stainless steel passivation for higher corrosion resistance and uniform appearance, to Medical-grade cleaning, we have solutions. As an important final step, we can clean complex components in a variety of shapes and sizes made of almost any material to produce minimal residue results that will exceed your cleanliness expectations.

Interested? Contact Us for a Quote.

Get in touch with us to learn more about how we can help you succeed. With our vast expertise and customer-first approach, we’re confident we can provide you with the exact services you need, when you need them.

Quality Above All.

The quality of the products we produce not only matters to you, it matters to us too. We take pride in providing our customers with exactly what they need to complete their projects, at the highest standards. To meet these standards of international quality across multiple industries and demonstrate our dedication to it, we are pursuing ISO 9001:2008 registration. Our team also actively applies continuous improvement methods to everything we do, and operates within the strict balance of efficiency and quality that allows our machining floor to be organized for the best results.